Gypsum

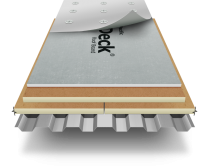

Wood

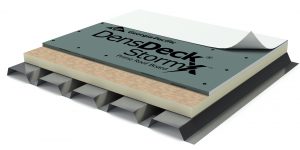

Commercial Roofs

Exterior Walls & Ceilings

Interior Walls & Ceilings

- Abuse/Impact

- Ceilings

- Fire-Rated Type C

- Fire-Rated Type X

- Lite-Weight

- Moisture Resistant

- Shaftliner

- Veneer Plaster Base

Industrial & OEM

Lumber

Roof Sheathing

Specialty

Technical

Search

Commercial Roofs

Exterior Walls & Ceilings

Interior Walls & Ceilings

Industrial & OEM

Lumber

Wall Sheathing