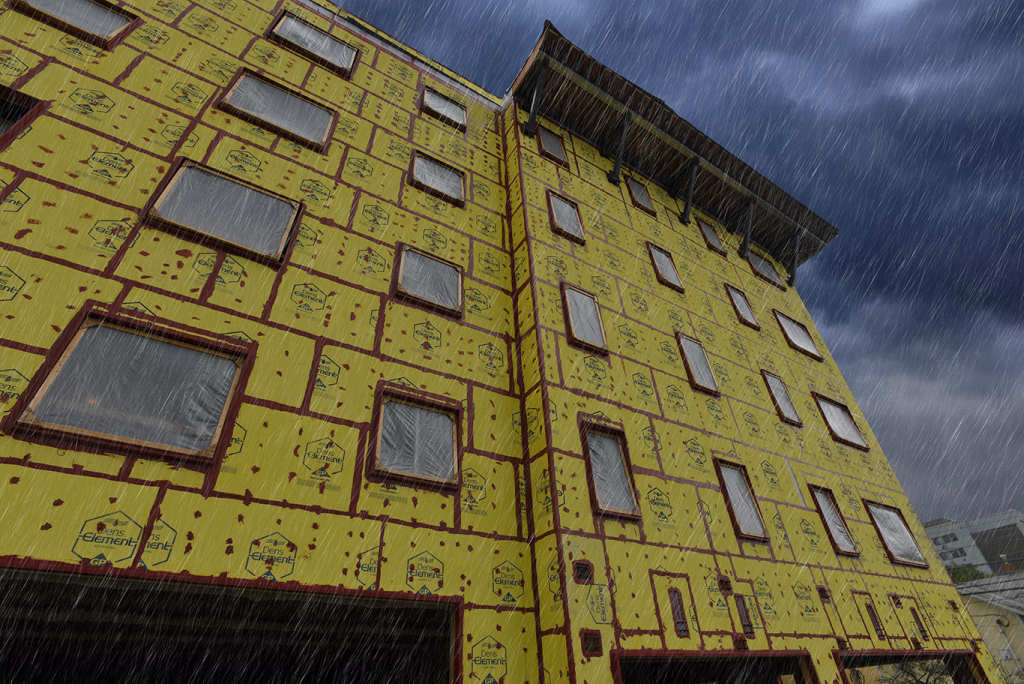

It’s important to have a wall assembly that’s strong enough to withstand the pressures of Mother Nature. But the real test is whether that assembly can maintain its durability even after years of wear and tear.

In passing the rigors of ASTM E331 testing in various applications, the DensElement® Barrier System has proven its ability to meet that challenge. ASTM E331 is performed twice in ICC-ES AC 212. First as a stand-alone test, second as a part of a 4-part test. In this 4-stage event, water penetration was tested after the DensElement® Barrier System was subjected to three other test methods—loading, racking, and environmental conditioning.

“It’s saying my system is good not only when it’s fresh and new; it continues to be good throughout the life of the building, regardless of all these weather conditions it will likely go through,” says John Chamberlin, senior product manager for the DensElement® Barrier System.

What is ASTM E331?

ASTM E331 is the standard test method for water penetration of exterior windows, skylights, doors and curtain walls by uniform static air pressure difference. The test determines a product’s resistance to water penetration under these air pressure differences, which can vary greatly.

The water penetration test involves spraying water onto the wall assembly and then applying different pressures to simulate wind-driven rain.

ICC-ES AC212 is comprised of a four-stage test in which the wall system gets banged up, bent in different directions and then exposed to prolonged heat and sustained winds and rain to artificially age the system. Then after the wall system has been fully beaten up, it undergoes the initial water penetration testing all over again. This exhaustive testing resulted in the evidence needed for ICC-ES to confirm the performance of the DensElement® Barrier System as a combination exterior wall sheathing, water resistive and air barrier system (ESR-3786).

Why is it important?

Buildings are constantly subject to changing pressures because of wind and other changes on the outside, and because of mechanical systems on the inside. These pressure differentials can suck in or push in water in from the outside, Chamberlin explains. ASTM E331 tests for the leaks that can compromise a wall assembly.

All walls need to have a water-control layer; this is the function the DensElement® Barrier System serves. But during construction of a building, it’s necessary to put holes in those walls – and, thus, in the wall’s water-resistive barrier – to create spaces for windows, doors, electrical wiring and plumbing components. With DensElement®, it’s also necessary to make holes in the WRB when fastening the system to the framing and cladding components.

To stop water from getting into those holes, PROSOCO FastFlash® liquid flashing can be used to seal joints, seams, penetrations and rough openings and maintain the wall assembly’s water-resistive properties.

ASTM E331 tests the resiliency of this assembled wall system. The test recreates weather conditions by spraying water onto the assembly and changing the pressures affecting the assembly at the same time. “The idea is that if our assembly passes the test, then we feel really good about the assembly performing well in real-life conditions when it is installed in a building,” Chamberlin says.

Testing at a glance in Accordance with ICC- ES AC212

The International Code Council requires that to meet ICC-ES AC212 the ASTM E331 test is performed twice – first as a standalone test, then a second time that includes a four-part test.

Test one (standalone test): This procedure tests the water penetration of the assembly, including windows, brick ties and penetration.

Test two (four-part test):

Because buildings go through plenty of stresses throughout their lifetime, the system is tested for water penetration in this four-part test:

- ASTM E1233- Loading: The wall panel is bent repeatedly to make sure it does not allow any leaks. This stage takes place 10 times.

- ASTM E72- Racking: This simulates wind blowing on the face of the sheathing; the system is repeatedly bent again, but in a different direction.

- Restrained Environmental Conditioning of Panel with WRB-AB-Environmental racking: The system is subjected to five cycles of 24-hour water spray and 24-hour radiant heat on structurally-tested panels.

- ASTM E331-Water penetration: After undergoing the first three stages, the wall system is tested one more time determine its resistance to water penetration under uniform static air pressure differences.

“The testing suggests that, when properly installed, the DensElement® Barrier System will continue to keep bulk water out of the building even in varying weather conditions and for the lifetime of the building,” Chamberlin says.

In addition to the required testing, the DensElement® Barrier System was able to pass ASTM E331 after fastener penetrations were added to accommodate different cladding attachments. The testing suggests that various cladding systems, such as rainscreens, over the DensElement® Barrier System will not create any additional risk of leaks.

“And all of that means that now you can have great protection against bulk water and unwanted air movement, but also a great appearance thanks to all the claddings you can put over the DensElement® Barrier System,” Chamberlin says.

For more information on ASTM E331 testing and additional testing data, check out our DensElement Barrier System Testing Matrix.

This article is intended solely as general information. Ultimately, the design and detailing of any project, assembly or system is the responsibility of a professional, and all projects must comply with applicable building codes and standards. For information concerning the limited warranty for the DensElement® Barrier System, visit www.denselement.com. GP Gypsum disclaims any responsibility or liability for the architecture, design, engineering or workmanship of any project, assembly or system.