How Gypsum Cover Board Helps Defend Your Commercial Roof Designs

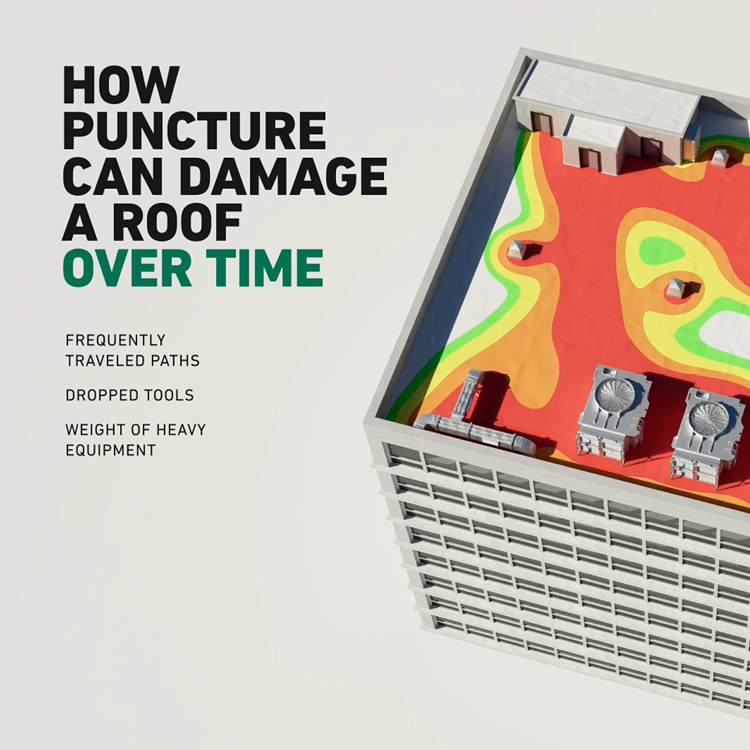

Roof damage comes in all sizes, from the smallest puncture to the largest gust of wind. While small punctures on a large commercial roof may not look threatening, they can lead to serious problems over time. Specifying materials to create a resilient roofing system can help to mitigate the most common causes of roof damage. An impact-absorbing layer like the fiberglass mat-faced gypsum used in DensDeck® Roof Boards can help you dramatically reduce potential threats to your designs. This rooftop investment also has long-term benefits. Find out why it’s worth the investment below.

Getting Stakeholders on Board

You can convince project stakeholders to greenlight the gypsum cover board you recommend—without the uphill battle. Beyond protecting your design intent, highlight what can happen when gypsum cover boards are value-engineered out of a project.

Point out the various roof-use scenarios:

- After a roof is installed, HVAC installation and maintenance can cause puncture damage.

- Solar panels also add to wear and can increase the risk of fire.

- While green roofs are becoming more popular, they need versatile roofing systems with a rigid substrate to handle the load.

Let your stakeholders know how weight-bearing enhancements increase the risk of puncture damage to a roof. Even small holes can let rain in while remaining hidden underneath the assembly. If moisture is allowed to spread, mold may grow and weaken the structure yet stay nearly invisible until it’s too late.

Your recommendation can do more than help prevent commercial roof damage to your designs. For your stakeholders, it can mean they save time and money in both the short and long term. During construction, your building product specifications can help ensure crews stay focused on new roof jobs instead of dealing with costly callbacks.

Guiding stakeholders to invest in gypsum roof boards can help them protect their margins and avoid delays on projects that are not yet in development. As for long-term benefits, your inclusion of the right substrate can mean your roof has the necessary structural support for weighty rooftop enhancements, as well as protection against the increased risk of damage they can bring.

When we put DensDeck® Roof Boards and HD ISO to the test, DensDeck Roof Boards held up to double the pressure of roof assemblies without a cover board and roof assemblies using HD ISO for a cover board.¹ This added impact protection to both the membrane and insulation of your roofing system design can help mitigate the risk of even small holes that can allow water to seep in.

Let your stakeholders in on these short- and long-term benefits so they see the return on investment when they agree to use the right assembly up front. Share how your recommendation to add an impact-absorbing layer, like the fiberglass mat-faced gypsum used in DensDeck Roof Boards, can help dramatically reduce damage and associated costs.

Stand by Your Specifications

Gypsum cover boards are not required in roofing assemblies, but your stakeholders need to know the consequences of value-engineering them out of your specifications. They may prevent the potential major expenses of roof repairs, replacement, and overwhelming damage that threaten the integrity of your projects. A recent FMI study found that using a cover board can save building owners an average of $1.40 per square foot in O&M costs over the lifespan of the roof.2 Your thoughtful material recommendations in the design phase can have a long-lasting impact on cost and performance.

While less-expensive solutions may seem attractive up front, stand by your gypsum roof board specification to improve the building’s resiliency, protect the owner’s investment and reinforce your reputation for creating attractive and durable designs.

For more information or to speak with a gypsum roof board expert, visit DensDeck.com/StopCallbacks

1 Internal Modified ASTM D4833 Slow Speed Puncture Test performed on January 23, 2023.

2 FMI Roof Cover Board Survey completed in May 2020. Actual results may vary.