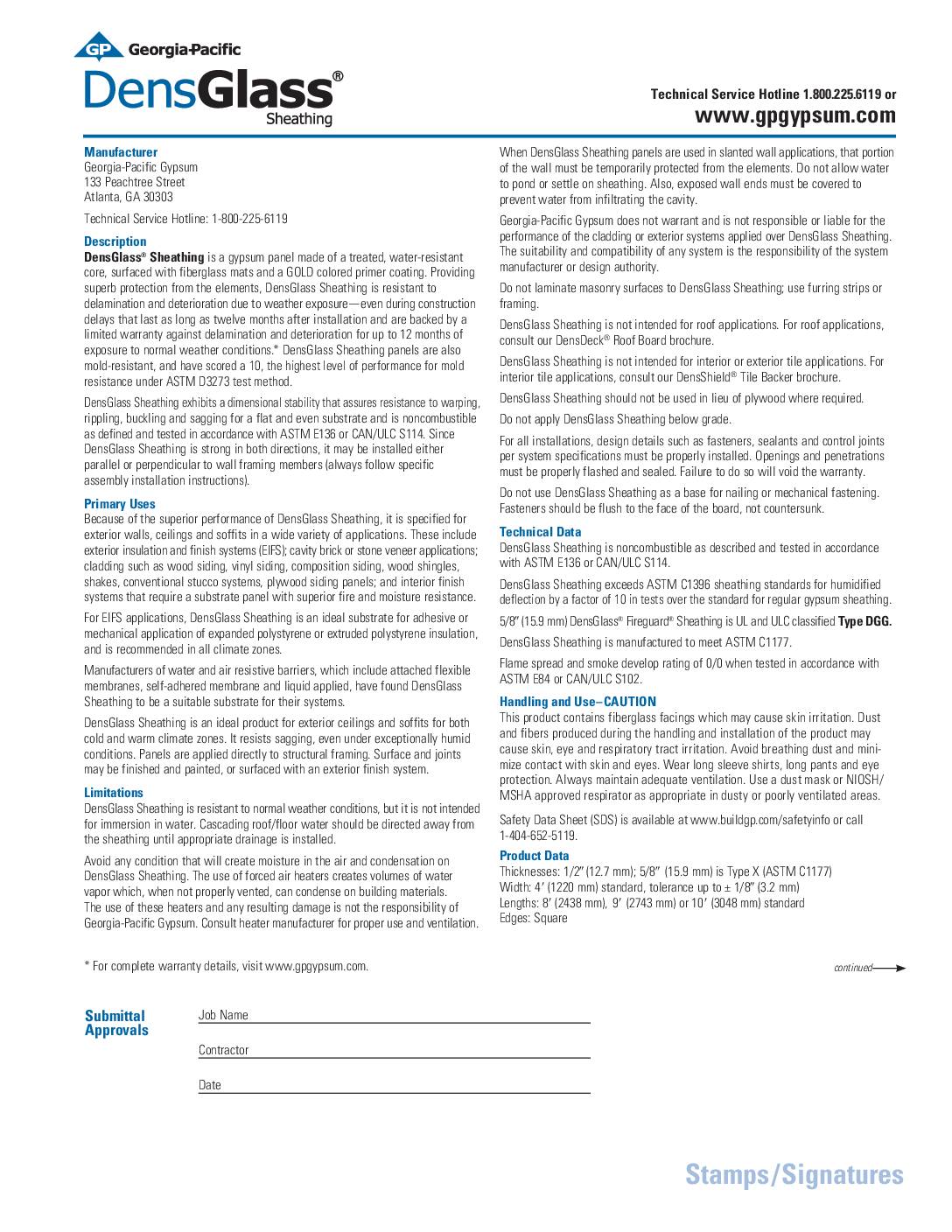

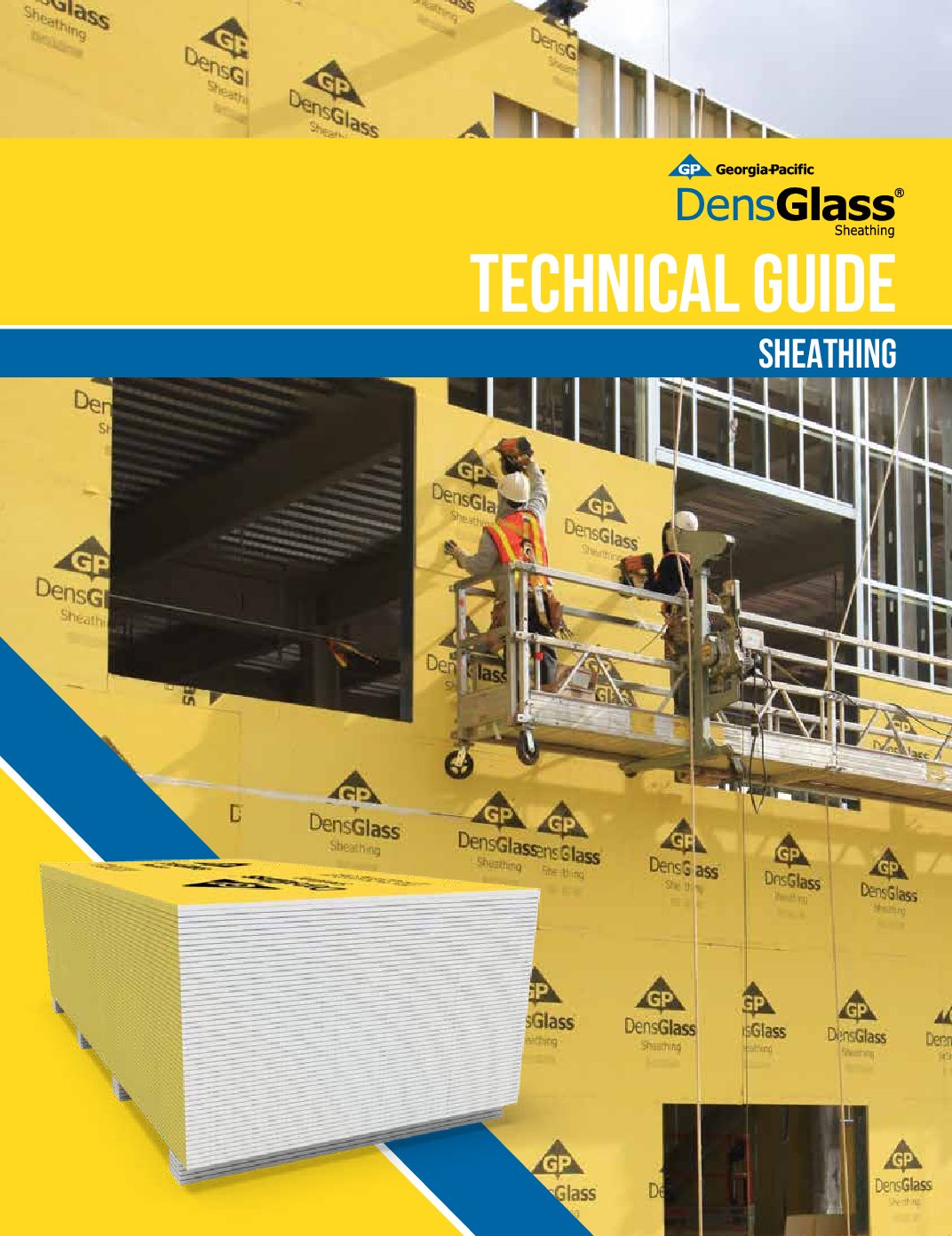

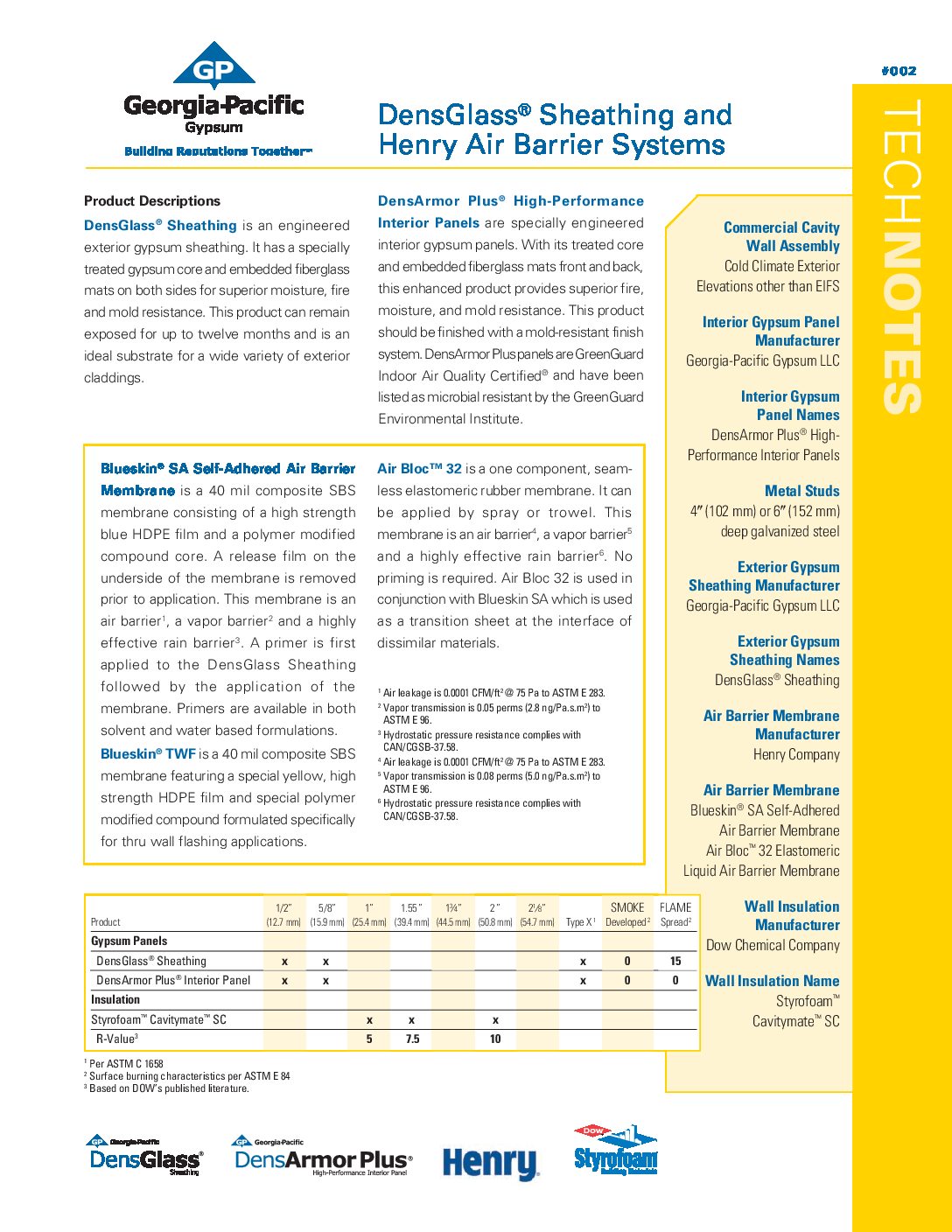

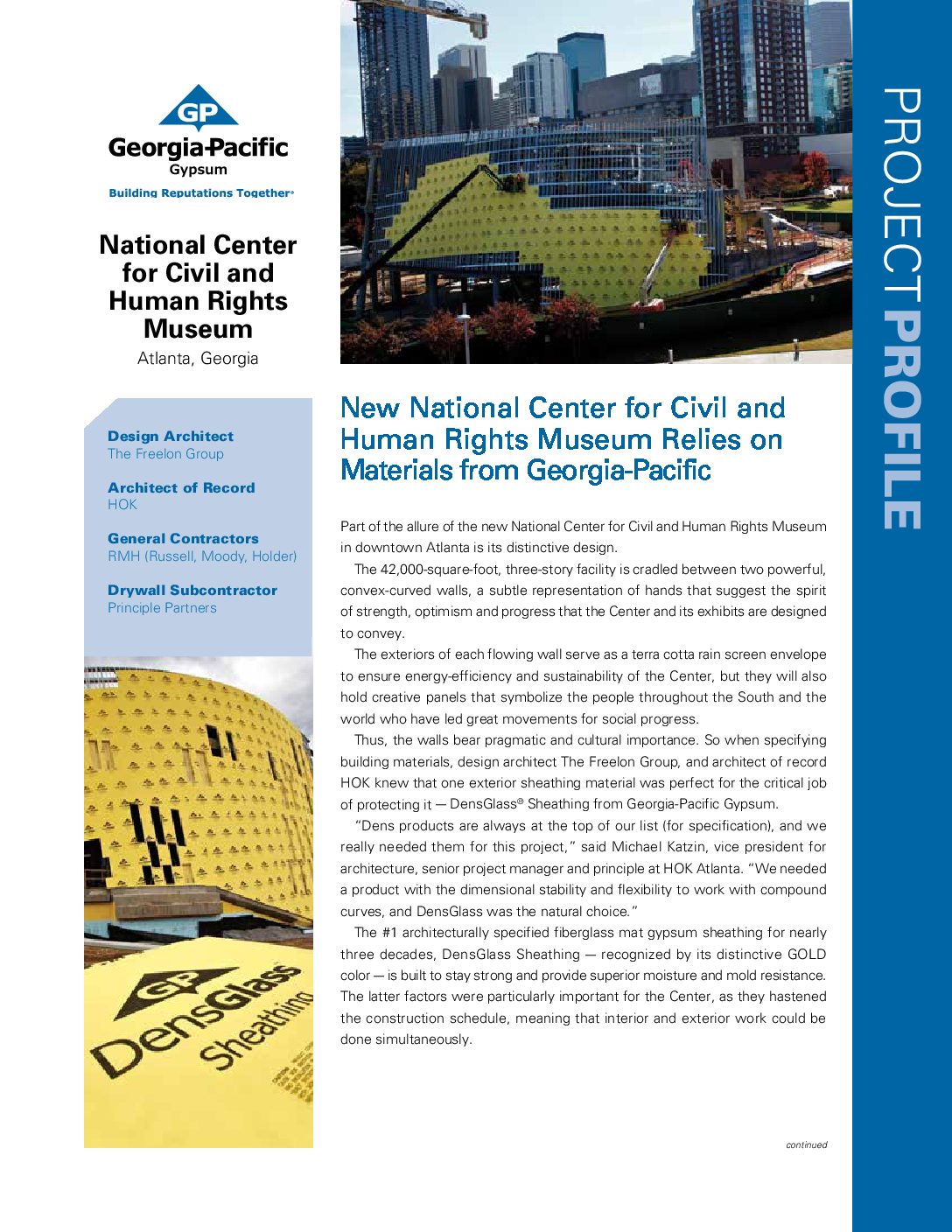

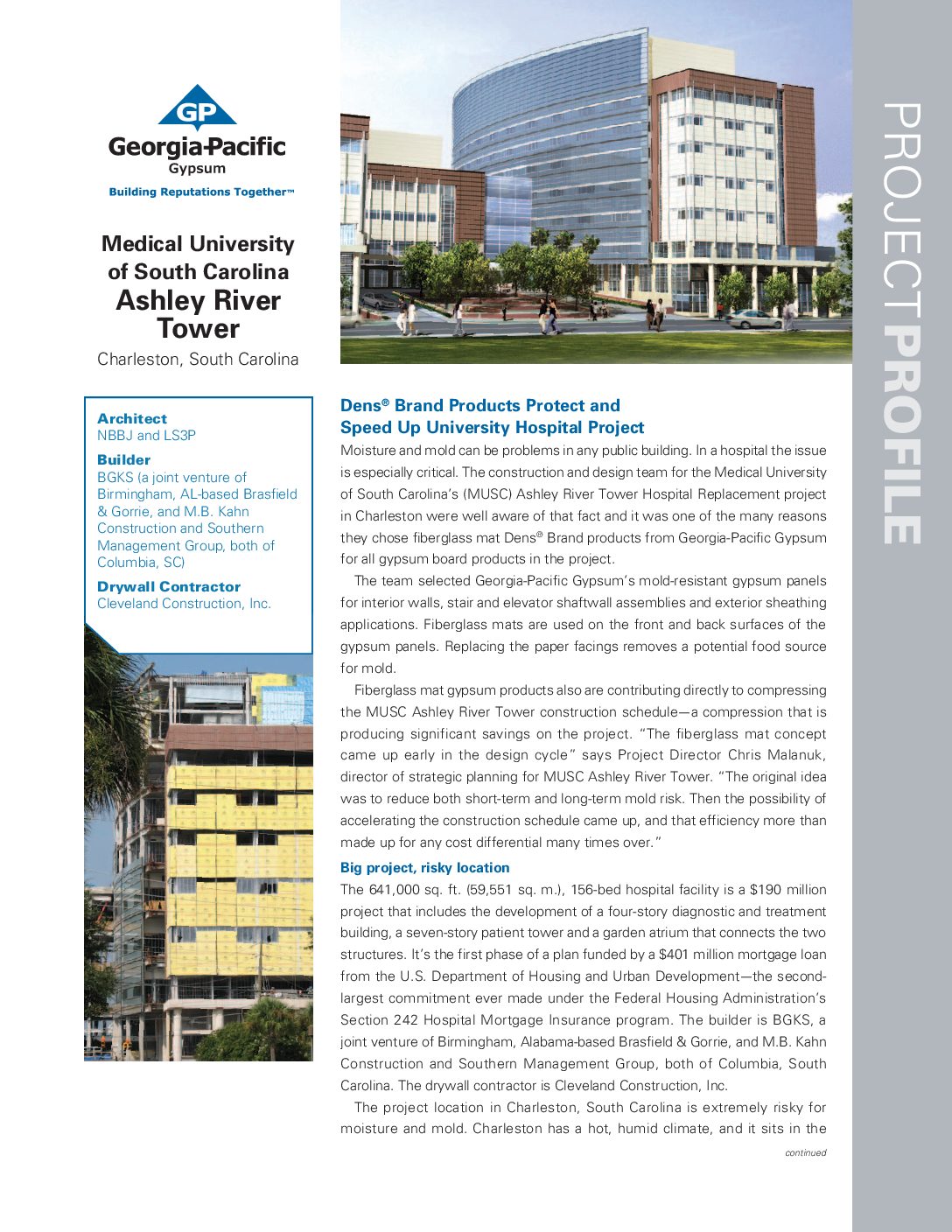

Widely recognized by the GOLD color, DensGlass® fiberglass mat gypsum sheathing has an exemplary track record that spans more than 30 years. It is a preferred substrate under brick, stone, stucco, siding and EIFS due to its ability to protect a structure against incidental moisture during and after construction. DensGlass Sheathing adds performance and durability to a wide range of fire-rated and non-fire-rated building assemblies. Dens® Solutions are industry trusted, high-performing fiberglass mat gypsum panels suitable for your wall, roof, ceiling and floor projects. Dens Solutions carry the mark of our valued heritage in Gold, as a visible standard-bearer of our position as the first manufacturer to create a fiberglass mat board and as a relentless innovator of strength and moisture resistant products for over 30 years. Dens Solutions answer building challenges with ingenuity.

1DensGlass® Sheathing panels have scored a 10 – the highest level of performance for mold resistance under the ASTM D3273 test method. It’s extremely resistant to rippling, buckling and sagging, even under humid conditions, which makes it particularly suitable for soffits. In actual tests, DensGlass panels exceeded ASTM C1396 standards for humidified deflection by a factor of five times over the standard for paper-faced gypsum sheathing.