The Smarter Sheathing System for Residential and Multi-Family Builds

When it comes to defying the elements, buildings are only as strong as the products used to protect them. Increase the quality and durability of residential and multi-family builds with Georgia-Pacific’s ForceField® Weather Barrier System.

Weather conditions threaten the structural integrity of every build, from single-family homes to multi-family projects. Residential and light commercial builders alike are looking for a more advanced way to protect their structures as they battle to stay ahead of weather, time and labor challenges. The problem is that common solutions, such as house wraps, self-adhered membranes and fluid-applied membranes, all have their own limitations.

Instead, builders are turning more toward integrated water-resistive barrier and air barrier (WRB/AB) systems. An integrated WRB/AB provides a critical line of defense against the elements. It reduces the risks of water damage and air leakage while preventing costly damage delays due to weather. By simplifying the approach in achieving a continuous building envelope, WRB/AB systems can better protect investments, reputations and tight timelines.

Leave Nothing to Chance

To deliver the level of quality and risk mitigation that builders desire from a WRB/AB, Georgia-Pacific has developed a high-performance sheathing system for wood-framed building needs. ForceField® Weather Barrier System is the all-in-one smarter sheathing system that helps protect against air and water intrusion, resists the effects of moisture on structural performance and creates a more energy-efficient structure.

Reduce the Risks of Water Damage

Solutions without water-resistive technology make builds vulnerable to water damage that can do more than leave unsightly stains on walls and ceilings. Water has the power to compromise the structural elements of the build.

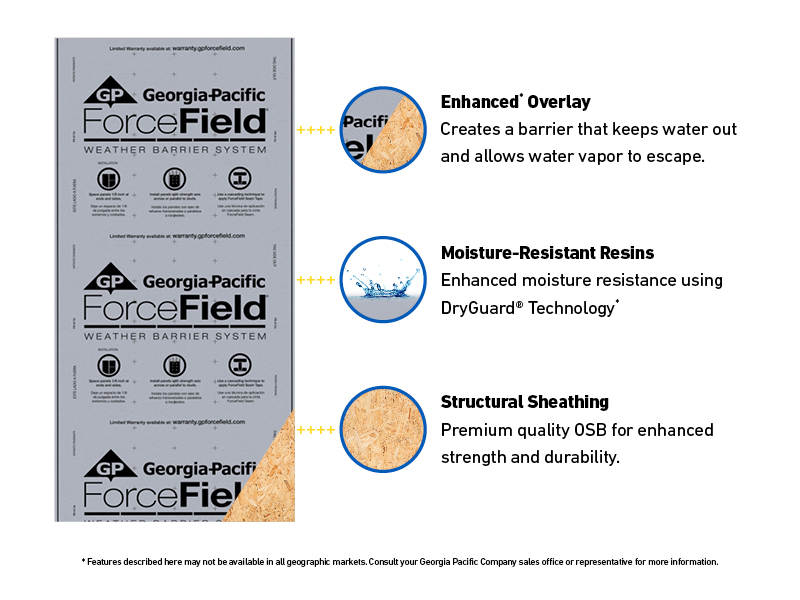

Drying in your build begins with ForceField® Panels featuring a 3-in-1 design that consists of:

- Structural sheathing for greater strength and durability

- Moisture-resistant resins with DryGuard® technology*

- A water-resistive overlay that helps keep water out and is vapor permeable

This innovative design promotes water holdout, and the panels start protecting your structure the moment they are installed.

Keep Builds on Schedule

Because the ForceField® Weather Barrier System creates a water-resistive barrier, crews can avoid the step of applying house wrap, reducing the number of trade professionals needed on a jobsite. Unlike house wrap, the ForceField® Panels don’t tear, peel or blow off in typical weather, so there’s no need to worry about retouching after windy days. Plus, the panels install easily like standard OSB or plywood, increasing the overall efficiency of the crew while adding to the integrity of builds. Staying on schedule, along with ease of install, leads to faster turnaround times on projects and increased profitability.

Minimize Air Leakage

To see the full benefits of integrated sheathing, accessories complete the system to prevent air infiltration and contribute to the continuity of building envelope control layers.

Installers can quickly and easily treat seams and joints with ForceField® Seam Tape Plus. ForceField® Flex Flashing Tape, ForceField® AT Flashing and ForceField® Corner Seal can also be used to treat every detail and make sure no gap is left behind. ForceField® Weather Barrier System is also compatible with our premium building envelope products, including DensDefy™ Liquid Flashing and DensDefy™ Transition Membrane.

A Warranty That Adds Another Layer of Protection

Once all seams have been treated to complete this smarter sheathing system, ForceField® Weather Barrier System creates a long-lasting, high-performance building envelope that stands strong against the elements. Plus, the ForceField® Panels and system accessories that are a part of the original building envelope are covered under a limited warranty from Georgia-Pacific. It’s all a part of our enduring commitment to offering quality, durable building products.

To discuss your jobsite needs and challenges, and to see ForceField® Weather Barrier System in action, visit GPForceField.com or contact us here for more information.

*Features described here may not be available in all geographic markets. Consult your Georgia-Pacific Company sales office or representative for more information.