Insider Tips on How to Optimize ForceField® Weather Barrier System and Accessories

Common misconception: An integrated WRB is more complex than house wrap.

Keep installation easy for your crew with a system that is solution oriented, one that allows you to choose from a range of accessories that help streamline construction while also providing much-needed versatility.

The WRB System That Helps Simplifies Construction

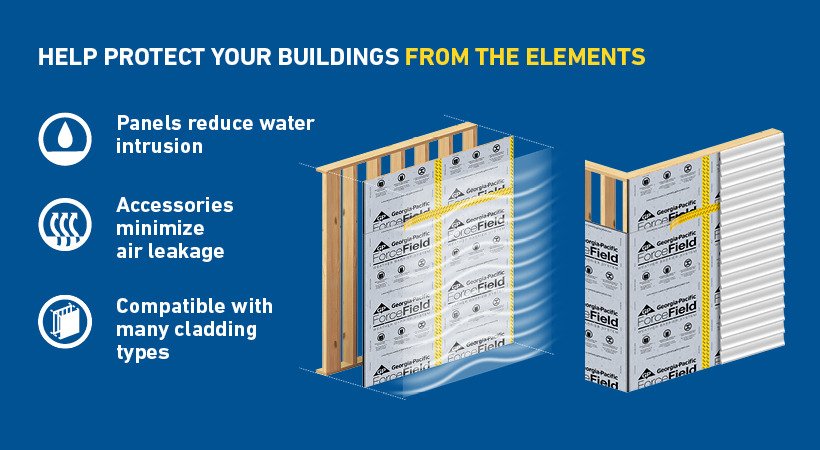

ForceField® Weather Barrier System, the integrated WRB sheathing system from Georgia-Pacific, is so simple and straightforward that you can dry-in an entire wood-framed structure with just one kind of panel and one kind of tape. Keep in mind, that includes walls and sloped roofs on multifamily and residential structures, so there’s no switching between materials or confusion about what goes where. On top of that, the system can be installed by just one trade.

While ForceField® Weather Barrier System can be simplified down to only the sheathing panels and one kind of tape to treat the joints, seams and rough openings, another advantage to the system is that you can scale up on accessories based on your structure’s needs. The system has a wide range of accessories to make life easier when it comes to tricky detailing like windows, inside corners and material transitions.

Let’s dive into how you get simplified construction with customizable accessories, all in one system.

The Integrated Sheathing Panels Take the Lead

You’ll always start with ForceField® Panels. These sheathing panels are made of premium OSB with moisture-resistant resins and an enhanced overlay. They’re ideal for walls and sloped roofs, so you can apply the panels all in one go. And they’re available in three lengths to help installation move quickly.

What that means is you eliminate the step of adding house wrap or roof underlayment while creating a barrier that helps keep water out at the same time. ForceField® Panels and Accessories may offer more advanced protection than house wrap, but your crew won’t need to know advanced techniques for installation. The panels install like standard OSB or plywood, so your team already has the skills to get them up. Then again, if they need additional guidance, our technical support is always available with experts ready to provide in-field, hands-on training.

Once your panels are up, you’ll want to treat the seams to help achieve a continuous building envelope. Run through your options, then pick and choose the accessories that best fit the needs of your crew, your budget and your structure.

What Makes Premium Tape a Top Choice

ForceField® Premium Tape is the best way to treat the joints, seams and rough openings of your ForceField® Weather Barrier System. This high-performance, self-adhered flashing tape can be used to treat panel joints and seams on walls and sloped roofs with conformability for bonding around curves and corners, such as windows. It is also AAMA-approved as flashing for penetrations and rough openings. ForceField Premium Tape offers exceptional durability, impact resistance and tear resistance once installed.

If you’re looking for a way to treat wall seams, joints and detailing penetrations, look no further. ForceField® Seam Tape is a pressure-sensitive coated polymeric film for walls that helps contribute to the continuity of your air and moisture barrier. Plus, it performs in temperatures as low as 0⁰F, so you don’t have to worry about halting progress when temperatures dip.

Get to know a few more accessories from Georgia-Pacific that work with the ForceField® Weather Barrier System.

How to Master Inside & Outside Wall Corners

Wall corners can be some of the most difficult areas to treat. But when you come up against a 90-degree angle, there’s no need to get bent out of shape.

Simplify the detailing of inside and exterior wall corners with the accessory that creates a “living hinge”: ForceField® Corner Seal. This semi-rigid polypropylene seal helps make your application more efficient. It has a pre-bent shape to allow for easier application and tapered edges to help with a smooth transition. ForceField® Corner Seal also adheres to panels with seam tape for additional protection against air and moisture.

Addressing Rough Openings

When it comes to rough openings, you have three excellent choices.

ForceField® Premium Tape comes back into the mix here as the top-tier product for treating windows and other rough openings.

Another top option is ForceField® Flex Tape, a conformable, peel-and-stick flashing tape that can be molded easily to fit odd angles and curved openings around doors and windowsill pan flashing. This high-performance butyl is designed to maintain the continuity of the air- and water-resistive barrier of your structures.

Finally, a premium, long-lasting option for sealing penetrations and joints comes from the line of DensDefy™ Products. DensDefy® Liquid Flashing is a waterproofing, adhesive and detailing compound that creates a highly durable continuous elastomeric flashing membrane. That means it’s ideal to protect door and window rough openings on walls, as well as penetrations and seams. It even eliminates the need for joint reinforcing tape, reduces installation time and can be applied by the same subcontractor who is in charge of installing the panels.

Continue to compare and choose from the full set of accessories that complete the ForceField® Weather Barrier System and help you get dried-in faster. To see how ForceField® Weather Barrier System and Accessories helped this residential construction team save time on the jobsite, check out this case study.

Or, talk to one of our experts to help you select and buy the materials you need for an integrated WRB on your next wood-framed project.