DryGuard® Enhanced OSB

Sturd-I-Floor

- OSB Single Floor with tongue and groove edge for easy installation.

- Enhanced OSB with additional moisture resistance to help prevent water-related issues such as thickness and edge swell.

- Available in both Tongue & Groove and square edge options to suit various installation needs.

- Excellent nail-holding ability.

- Provides stiffness and strength to floor systems.

- Black edge seal helps prevent moisture intrusion.

- Moisture-resistant panel, ideal for your flooring projects as well as DIY projects.

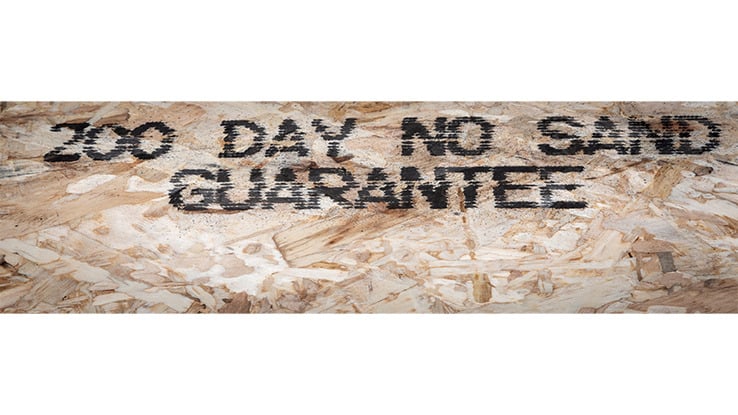

- 200-day no-sand warranty.

Product Details

DryGuard® Enhanced OSB Sturd-I-Floor is engineered with advanced moisture resistance to provide a solid foundation for any building project. Available in both Tongue & Groove and square edge options, DryGuard® offers flexibility to meet your specific installation needs. Our tongue and groove design ensures a seamless fit where used, while the panel’s robust resistance to thickness swelling helps maintain long-term performance.

FEATURES AND BENEFITS

- Moisture Resistance: Multi-layer protection with a black edge seal reduces moisture absorption.

- No-Sand Guarantee: Backed by a 200-day no-sand warranty to save you time.

- Durability: Rated for Exposure 1 bond durability, perfect for protected applications and construction delays.

- Nail Retention: Ensures secure fastening for a long-lasting build.

- Sustainable Sourcing: Manufactured with wood certified to SFI® or FSC® fiber sourcing standards.

Product Specifications

Performance Attributes

| Classification | Exposure 1 – Rated sheathing suitable for uses not permanently exposed to the weather. Panels classified as Exposure 1 are intended to resist the effects of mositure on structural performance as may occur due to construction delays, or other conditions of similar severity. |

| Code Fire Classification | Class III or C |

| Flame Spread Rating | 76-200, smoke developed index <450 |

| Building Code Compliance | PS 2-18 |

| Testing Agency | APA® – The Engineered Wood Association |

Building Code Performance Categories, Panel Thickness

| 19/32 CAT | 0.578” (14.68 mm) |

| 23/32 CAT | 0.703” (17.85 mm) |

Physical Properties

| Square Edge | 3′-11⅞″ (1.216 m) x 7′-11⅞″ (2.435 m) |

| Tongue & Groove | 3′-11½″ (1.206 m) x 7′-11⅞″ (2.435 m) |

| Length/Width Tolerance | ±1/16” (±1.6 mm) |

| Straightness Tolerance | ±1/16” (±1.6 mm) |

| Squareness Tolerance | ±1/8″ (±3.2 mm) |

CERTIFICATIONS

Resources

FAQs

OSB is not recommended for outdoor projects. OSB is considered an Exposure 1 panel, which means they may be used for applications where construction delays may be expected prior to providing protection. But OSB is not suitable for long-term exposure to the weather.

Yes, Georgia-Pacific plywood and OSB panels only use moisture resistant adhesives that contain no added urea formaldehyde resins, and are therefore exempt from U.S. EPA and California formaldehyde regulations due to their very low emission rates.

Plywood and OSB panels from Georgia-Pacific are made from wood sourced through a system that is third-party certified to the Sustainable Forestry Initiative® procurement standard.

The number of panels in a unit of OSB varies depending on the type and thickness of product. On sheathing products, the piece count is typically stenciled on the side of the unit. Other products have corrugated side protectors that should indicate piece count. If you need a piece count and neither of those are visible, please contact GP at 800-284-5347.

Related Products

Need Technical Help?

Gypsum Products

OSB/Plywood Products

Wood Products

Lumber Products

Newsletter Sign Up

Subscribe for the latest news and insights.