DensGlass® Shaftliner

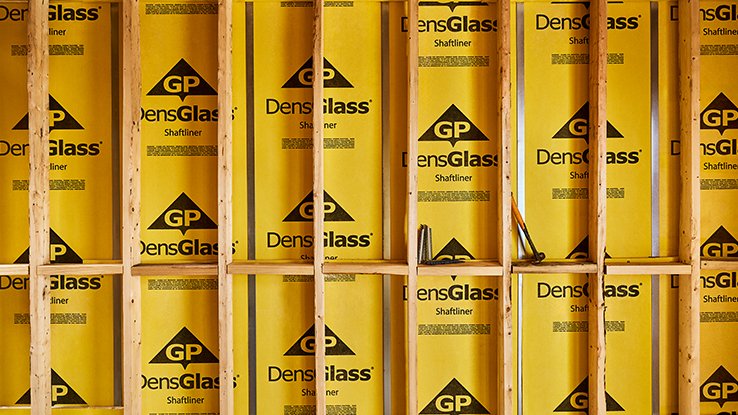

- Perfect for use in elevators, air shafts, stairwells, and mechanical rooms in industrial buildings.

- Can be utilized as firewalls between office, warehouse, and manufacturing areas.

- Great as horizontal membranes for corridor and stairway ceilings and under mechanical equipment where fire ratings are required.

- Suitable for semi-exposed installation before the building envelope is weather-tight.

- A1 Reaction to Fire classification in accordance with BS EN 13501-1.

- Flame Spread 0, Smoke Developed <0 when tested according to ASTM E84 or CAN/ULC S102.

- Non-combustible when tested in accordance with ASTM E136 or CAN/ULC S114.

Product Detail

DensGlass® Shaftliner Panels are made from durable fibreglass mats, boast a top-tier Euroclass reaction to fire A1 classification, offering optimal safety for your building projects. In addition to exceptional fire performance, DensGlass® Shaftliner Panels provide superior mould and moisture resistance, ensuring a robust and long-lasting solution.

These panels are just the right addition for lining shaftwall/stairwell enclosures. Thanks to their space-saving design and simple installation process, your construction projects will not lag even during colder weather conditions. Moreover, their moisture resistance makes them ideal for installation in semi-exposed areas before the building envelope is sealed—embracing the elements without fear of delamination or deterioration for up to 12 months.1

Designed specifically for elevator and air shafts, stairwells, and mechanical rooms in industrial buildings, these panels meet the requirements of spaces with greater wall heights. They serve excellently as firewalls between office, warehouse, and manufacturing areas. Additionally, DensGlass® Shaftliner Panels can also be used as horizontal membranes for corridor and stairway ceilings and under mechanical equipment where fire ratings are required and normal suspension support may be a challenge.

DensGlass® Shaftliner Panels also hold an A1 Reaction to Fire classification in accordance with BS EN 13501-1, Flame Spread 0, and Smoke Developed <0 when tested according to ASTM E84 or CAN/ULC S102. In terms of non-combustibility, these panels have been proven to exceed expectations when tested in accordance with ASTM E136 or CAN/ULC S114. Trust DensGlass® Shaftliner Panels to provide you with the safety, reliability, and durability your construction project needs.

Product Specifications

PERFORMANCE ATTRIBUTES

| R Value3 | ft2•°F•hr/BTU (m2•K/W): >.65 (0.115) |

| Flexural strength, minimum Parallel, lbs.f. (N) Perpendicular, lbs.f. (N) | ≥80 (356) ≥230 (1023) |

| Surface Burning Characteristics Flame Spread, Smoke Developed (per ASTM E84 or CAN/ULC S102) | 0/0 |

PHYSICAL ATTRIBUTES

| Length2 | 8′ (2440 mm) to 12′ (3658 mm) ± 1⁄4“ (6.4 mm) |

| Width4 | 24″ (610 mm) |

| Thickness | 1″ (25.4 mm), ± 1⁄32“(0.8 mm) |

| Weight | 4.0 (20) |

| Edge | Double Bevel |

PERFORMANCE ATTRIBUTES

| R Value3 | ft2•°F•hr/BTU (m2•K/W): >.65 (0.115) |

| Flexural strength, minimum Parallel, lbs.f. (N) Perpendicular, lbs.f. (N) | ≥80 (356) ≥230 (1023) |

| Surface Burning Characteristics Flame Spread, Smoke Developed (per ASTM E84 or CAN/ULC S102) | 0/0 |

PHYSICAL ATTRIBUTES

| Length2 | 8′ (2440 mm) to 12′ (3658 mm) ± 1⁄4“ (6.4 mm) |

| Width4 | 24″ (610 mm) |

| Thickness | 1″ (25.4 mm), ± 1⁄32“(0.8 mm) |

| Weight | 4.0 (20) |

| Edge | Double Bevel |

CERTIFICATIONS

Certifications may vary by production location, please contact local representative for more information.

1.For complete warranty details, visit www.buildgp.com/warranties

2.Lengths normally stocked are 88, 108, and 128. Special lengths up to 148may be available with lead times and minimum runs that vary by plant.

3.Tested in accordance with ASTM C518.

4.Represents approximate weight for design and shipping purposes.

Resources

Related Products

Need Technical Help?

Gypsum Products

OSB/Plywood Products

Wood Products

Lumber Products

Newsletter Sign Up

Subscribe for the latest news and insights.