The Blower Door Test: Measuring Building Airtightness

Why Airtightness?

Knowing your building’s airtightness has become increasingly important as energy codes have been updated. Air tightness is defined as, “the degree of air leakage into and out of the building’s thermal enclosure which separates conditioned space from the outdoors.”1

Air leakage can be caused by wind, temperature differences, mechanical equipment like fans and even construction errors.2 Having a good air sealing strategy can help minimize leakage.2

Tighter buildings increase energy efficiency by decreasing the work of heating and cooling systems. This can contribute to lower utility costs for homeowners. For multifamily buildings, knowing the airtightness can also help determine the correct HVAC unit size, which may save building owners from buying larger, more powerful units they don’t need. Airtight buildings can also be more comfortable for occupants and, with the right ventilation system, improve indoor air quality.3

The good thing is that airtightness can be tested to find out the leakage rate of your building. The most common test used today is the blower door test.

What Is the Blower Door Test?

Blower door tests are used in the building industry to find out how much air is entering or escaping from a building. A blower door is a powerful fan that is mounted into the frame of an exterior door on a building.4 The fan is calibrated to either pull air out of the building (depressurization) or push air in (pressurization). Depending on the test being performed, the higher outside air pressure would flow in through all unsealed gaps, cracks and openings, or the higher inside volume of air would leak out.

Residential building codes in some states require a blower door test for new homes. Most federally funded projects also require a blower door test to be performed. Energy auditors can use these tests to help determine a home’s airtightness and see where air leaks occur. Having your structure properly sealed can help reduce the air leakage rate and drafts, conserve energy consumption, avoid moisture problems and keep pests from getting inside.4

Testing the ForceField® Weather Barrier System

Georgia-Pacific’s ForceField® Weather Barrier System is an integrated weather-resistive barrier (WRB) sheathing system made up of sheathing panels with a built-in air- and water-resistive barrier, and seam tape to seal your building envelope.

Designed to better protect homes from air and water intrusion, it recently was put to the blower door test to see how it performed against conventional oriented strand board (OSB) and house/building wrap.

Home Innovation Research Labs conducted the tests used to compare ForceField® Weather Barrier System to OSB wood panels and house wrap. Phase one tested a house that had OSB engineered wood wall sheathing with standard house wrap. Phase two tested the same house configuration with ForceField® Weather Barrier System on the exterior walls.

The study house was prepped with sealed drywall ceilings, caulked top and bottom plates, taped floor area seams, and installed wall systems and windows. The house wrap was taped at seams and edges but left unsealed at the top.

The tests measured air tightness by pressurizing and depressurizing the house while recording airflow and air changes per hour at 50 Pascals (ACH50).

Test Results: ForceField® Weather Barrier System vs. OSB and House Wrap

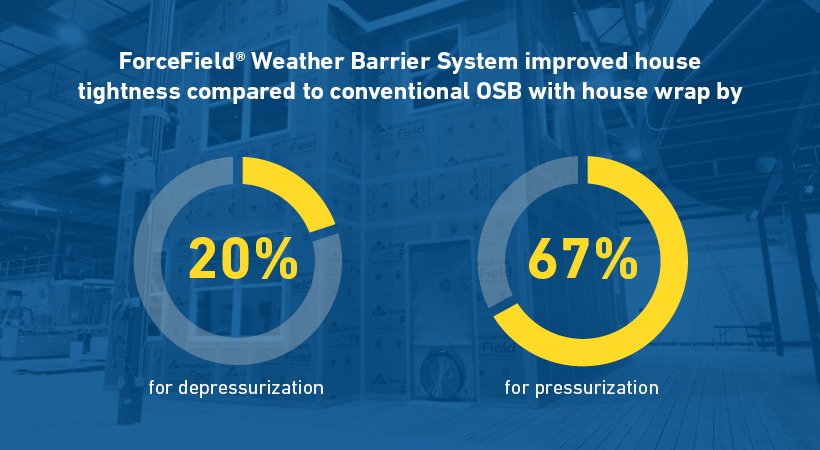

The tests found that ForceField® Weather Barrier System improved house tightness compared to conventional OSB with house wrap by 20% for depressurization (2.0 ACH50 vs 2.5 ACH50) and by 67% for pressurization (2.1 ACH50 vs. 6.3 ACH50).

The results indicate that Home Innovation Research Labs’ study house is a reasonable representation of a typical new home constructed to current building codes. For example, the OSB and house wrap depressurization result of 2.5 ACH50 is within the 2021 International Energy Conservation Code’s (IECC’s) prescriptive requirements of 3 ACH50 for Climates Zones 3-8 and 5 ACH50 for Climate Zones 1-2.

It’s also important to keep in mind that the intent of the tests was to compare two types of wall construction methods. Results will vary for other house configurations and for completed buildings with wall cavity insulation, drywall, interior trim and exterior wall cladding already installed.

Contributing to Atlanta Habitat’s 50 HERS Rating

After Home Innovation Research Labs conducted the blower door testing, ForceField® Weather Barrier System was donated to Atlanta’s Habitat for Humanity. It was evaluated again on the Habitat building, this time as part of a comprehensive Home Energy Rating System (HERS) test. The lower the HERS score, the more energy efficient a building is. Scores are determined during an extensive energy audit, testing the insulation levels, air leakage, HVAC efficiency, lighting, windows and appliances of a house.5 A blower door test is also part of this assessment.

Jim Blackstone, senior vice president of housing and operations at Atlanta Habitat, said, “Earning a 50 HERS (Home Energy Ratings Score) Index Score (initial cap per HERS website) for this home reflects our commitment to leveraging what we’ve learned through the years to improve every facet of our construction process from site design to floor plans. With the average energy cost savings of $1,605, the 50 HERS rating means this home is two times more efficient than other comparable homes and represents the lowest index score for Atlanta Habitat since starting this performance rating system. The home also received EarthCraft certification because of its construction practices and design features including the lowest blower door performance metric achieved in Atlanta Habitat’s history.”

More Advantages

Not only does ForceField® Weather Barrier System help with energy efficiency, but it can also simplify the installation process compared to OSB and house wrap. Home Innovation Research Labs also tested the two methods for installation speed, known as the Time Motion Study. It took the team nearly 18 hours to install traditional OSB and house wrap, but under 14 hours to install ForceField® Weather Barrier System. That’s a 20% difference in time savings.

ForceField® Weather Barrier System is also versatile. It can be installed as a wall and sloped-roof sheathing on single-family and multifamily homes. And since there’s no switching between materials, it requires fewer trips around the building. Plus, other trades don’t have to wait for installers to finish or retouch any rips and tears like with conventional building wrap.

To find out more about the blower door test and achieving air and water control for your building, check out the AIA CE course, Finding Design and Construction Efficiencies with Integrated Weather Barrier Systems.

1 https://www.iccsafe.org/wp-content/uploads/proclamations/TN02-Building-Tightness_pdf.pdf

2 https://buildingenergyexperts.co.uk/resources/air-leakage/

3 https://www.energy.gov/energysaver/air-sealing-your-home

4 https://www.energy.gov/energysaver/blower-door-tests

5 https://sips.premierbuildingsystems.com/blog/hers-score-unlocking-the-value-for-building-owners