DensDeck® Roof Boards Vs. HD ISO: Why A Gypsum Cover Board Is Your Better Option

Recommending the right materials can make or break your reputation for installing resilient roofing systems. From dropped tools during maintenance to the risk of fire and storm damage, commercial low-slope roofs are being asked to handle more today than ever before.

Using a fiberglass mat gypsum substrate like DensDeck® Roof Boards instead of a foam cover board like HD ISO (high-density polyisocyanurate) can help increase the durability of your roofing system. It can also help you—and all project stakeholders—avoid preventable problems in the future.

Compared to HD ISO, gypsum cover boards do a better job of mitigating damage and protecting your building from wind uplift, hail, punctures, foot traffic, and fire. Here’s why:

Supports Your Rooftops Today and Tomorrow

The landscape of a commercial low slope roof can change a lot over its lifetime. It’s highly likely that a rooftop will endure some kind of stress, like HVAC and solar installations, or even becoming a green roof. Weighty rooftop equipment and the foot traffic associated with their maintenance need a solid foundation. When comparing cover board materials like foam-based HD ISO versus a gypsum board like DensDeck® Roof Board, HD ISO cannot provide the rigid support and puncture resistance that glass-mat gypsum can.

DensDeck® Roof Boards have 8 to 11 times greater compressive strength than HD ISO1. Compressive strength (often measured in PSI) measures the amount of force a material can withstand before it cracks or breaks. The higher it is, the better a material will be at resisting punctures, supporting static equipment, and handling the burden of foot traffic.

“What are you going to ask that roof to do for the next 15 to 20 years? Are you going to add components like HVAC or solar onto it? Or are you going to be in an area where you have really increased negative weather patterns? Applying that long-term asset valuation is critical to deciding what roofing system you should install on your building.”

Greg Hudson, Director of Commercial Sales for Georgia-Pacific Gypsum

Building owners who are mindful about maximizing their asset investment should know about the negative impact that less robust materials can have on the longevity of their roofing systems. And no matter the building type, the roof you install is always protecting something valuable inside. Schools, data centers, hospitals, hotels and warehouses should especially consider the future state of their rooftops, whether it’s a new project or a re-roof.

Plus, by 2028, the U.S. solar industry is expected to triple in size.2 The heft of solar installations can damage a roof without adequate support. A solar array requires maintenance, which can increase the threat of puncture damage. It increases rooftop fire risk simply because it produces electricity. Building owners will also have to bear the cost of solar panel removal and reinstallation during re-roof jobs if their roof and the solar panels have different lifespans.

Gypsum roof boards are the best option to handle these combined risks.

“The insulation is typically the most expensive component of a low-slope roofing assembly. When using HD ISO as a cover board, you’re protecting your foam insulation with more foam on top. Yes, HD ISO happens to be 100 PSI compared to 20 PSI for standard polyiso insulation. But our gypsum cover boards start at 900 PSI. If it were my roof, I’d want to protect the insulation with rock, rather than with more foam.”

– Ben Williams, Building Envelope Manager at Georgia-Pacific

Offers Better Protection From the Elements

Extreme weather events like severe storms have been increasing across the country since the 1980s.3 In addition to enhanced strength that can help resist damage from hail and flying debris, DensDeck® Roof Boards have a strong mat-to-core bond that helps protect against wind uplift during rough weather. They also have a flexural strength range from 100 to 200 LBF (pound-force), compared to the 20 to 40 LBF for HD ISO.

Flexural strength determines the flex or bending properties of a material. Higher flexural strength can increase a cover board’s flute-span capability while guarding against wind uplift. This helps protect your roof from membrane delamination and fastener withdrawal. HD ISO’s lightweight foam can’t provide the same level of flexural strength and wind-uplift resistance.

For even more protection against extreme weather, DensDeck® StormX™ Prime Roof Board is FM classified for Very Severe Hail (VSH) in approved single-ply assemblies. Meanwhile, HD ISO is not approved for VSH.

Goes Beyond a Class A Fire Rating

One of the most dangerous threats to a commercial low-slope rooftop is the risk of catching fire. Fire can spread quickly from nearby buildings or vegetation—it just takes one burning ember and the right conditions for a roof to catch fire.

While many roof assemblies are rated as “Class A,” it is important to know that not all Class A assemblies are the same. Stakeholders need to think beyond “fire resistant” and consider “noncombustible” when it comes to a cover board.

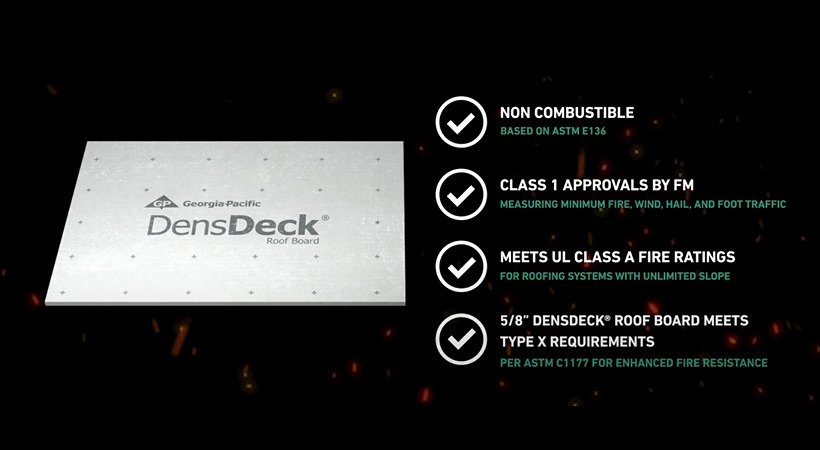

DensDeck® Roof Boards are noncombustible per ASTM E136. Their gypsum core and fiberglass mat facers help to stop the spread of fire and mitigate the risk of rooftop damage from every direction.

DensDeck® Roof Boards also are not chemically treated with fire retardants—gypsum is naturally noncombustible. On the other hand, since HD ISO is made with foam insulation, it is combustible and will smolder and burn under certain conditions.

Considering the benefits and risks, it’s clear that using anything less than high-performance gypsum roof boards can put your roofing assembly, the building owners’ investment and building inhabitants at risk.

Need more proof? See how the two cover boards compare in fire tests at DensDeck.com/Risky.

1 https://www.polyiso.org/page/500SeriesHDCoverBoards *Current specification as of 1/2024.

2 https://www.seia.org/research-resources/solar-market-insight-report-q2-2023#:~:text=Over%20the%20course%20of%20our,of%20year%2Dend%202022

3 https://www.ncei.noaa.gov/access/billions/